All subsystems have received a conformal coating treatment, marking an important step in ISTSat-1's journey to space!

Conformal coating is a thin polymeric film which conforms to the contours of a printed circuit board to protect its components. Why do we need to apply conformal coating? It’s used as a protective barrier against environmental contaminants, such as particles, dust, moisture, etc.

Particles that settle onto electronic modules during production, ground testing, launch or buoyant particles in the zero-gravity space environment may cause short-circuits, which could eventually lead to the malfunctioning of the spacecraft. Furthermore, overtime moisture and corrosive vapors may result in corrosion of metals in PCB assemblies.

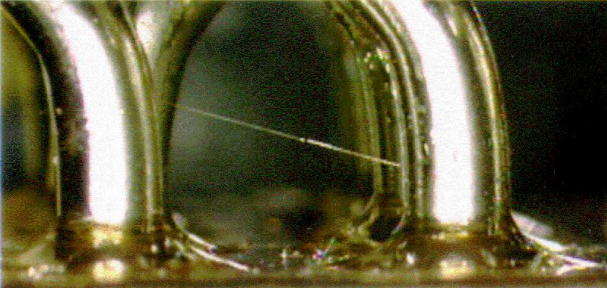

One particular phenomenon that affects spacecrafts is the formation of “tin whiskers”. A single accepted argument that explains the formation of these structures has not been established, although this phenomenon is known since the 1940’s.

Conformal coating stops all these situations from occurring.

But conformal coating also has its downsides. For one, it becomes very hard, or sometimes impossible, to fix or modify any hardware component, since it is covered in polymeric film.

Having done this treatment in all subsystems is a great step forward into the development of ISTSat-1, showing that our students are confident that hardware-wise, the satellite is near-completion!